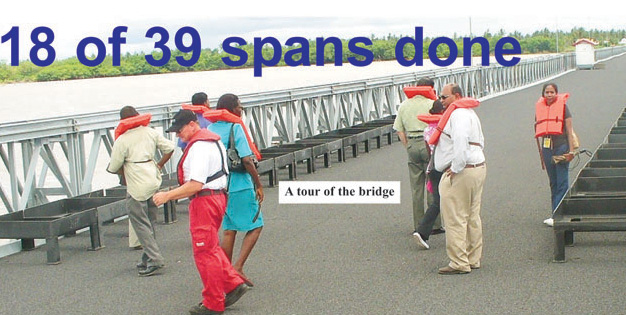

Although there have been delays in the construction of the Berbice Bridge, officials are confident that the September deadline would be met.Yesterday, officials from the Berbice Bridge Company Inc (BBCI) and the contractors, Bosch Rexroth and Mabey & Johnson took the media on its second tour of the structure. The first tour was held on October 18 last year when only one span [span three] had been installed.

Although there have been delays in the construction of the Berbice Bridge, officials are confident that the September deadline would be met.Yesterday, officials from the Berbice Bridge Company Inc (BBCI) and the contractors, Bosch Rexroth and Mabey & Johnson took the media on its second tour of the structure. The first tour was held on October 18 last year when only one span [span three] had been installed.

Bert Carter, chairman of the technical team said 18 spans, including the high span have already been installed out of a total of 39.

The original design of the bridge, which is said to have a lifespan of over 30 years and costs almost US$40 M, was for the high span to be positioned on the western end of the bridge.

But the design was adjusted for the high span to be placed at the eastern end and the erection of the platform for the high span is still in progress.

The change was made to facilitate a better flow of the river traffic.

The last section of the bridge to be constructed is the retractor span. Carter said that upon the completion of the high span, maritime traffic, especially from the bauxite company, Oldendorf would be able to pass under the high span unimpeded as installation of the other spans continues.The height under the retractor span is 40 feet while the distance between the two pontoons that support the high span is 120 feet. The high span would have to be linked to sloping spans on both ends.

The last section of the bridge to be constructed is the retractor span. Carter said that upon the completion of the high span, maritime traffic, especially from the bauxite company, Oldendorf would be able to pass under the high span unimpeded as installation of the other spans continues.The height under the retractor span is 40 feet while the distance between the two pontoons that support the high span is 120 feet. The high span would have to be linked to sloping spans on both ends.

According to Carter, the contractors are experiencing difficulties pushing the anchor to the required depth at the eastern end as the soil on the river bed is too hard.

Asked about walkways being erected on the bridge, chairman of BBCI, Geeta Singh-Knight stated that it “would not be practical and feasible…”

The company would be mobilizing and training almost 60 staff to manage and maintain the bridge for the next 21 years.

Singh-Knight said that the contractor would be handing over a fully lit bridge, including on the high span [and under high span for the ships] and retractor span as well as lighting on both ends of the access roads.

Navigation lights would also be installed on the cluster piles that were installed to guide vessels under the high spans and to protect the structure from accidental collisions.

Rawleston Adams, senior engineer with the Ministry of Public Works stated that the contract for the road project was signed for US$8.7 M and is undertaken by Dipcon Contracting Company. He said the access road on the D’ Edward end is about 70% completed while the road at the eastern end is approximately 40% completed.

He pointed out that the road is expected to be completed in two phases – the asphalt project by the first week in September, in time for the commencement of the bridge operations.

The contract completion, he said is set for April 2009, “giving the contractor another six months in terms of tidying up to install street lights and mark the road…”

Adams said the Palmyra and Crab Island road have already been linked and recently a truck drove from one end to the other.

He noted that while sourcing reef sand has been a hindrance, the contractors have the weather in their favour and they are trying to make maximum use of it.

BBCI’s six common shareholders are Colonial Life Insurance Company (CLICO), the NIS, the Hand in Hand Fire Insurance Company, Secure Inter-national Finance, Demerara Engineers & Contractors Limited (a subsidiary of DDL), and New GPC.

Other investors in the project are Republic Bank Limited, the Guyana Bank for Trade and Industry, Citizen Bank, Demerara Bank, Bauxite Company of Guyana Inc (BCGI), Hand in Hand Trust Corporation, the Guyana Geology and Mines Commission (GGMC) and the New Building Society (NBS).

The average toll for a vehicle will be around $1,400 [costs would vary for different classes of vehicles] but no charge will be levied for individual passengers. This amount was calculated on the basis of a formula intended to secure sufficient revenue to cover all operating and maintenance costs, return on investment and repayment on financing.

Singh-Knight said that the contract amounts are fixed and changes in procurement costs wouldn’t change anything. She said that BBCI hopes to use an automated system or an easy-pass system rather than paper ticket payment of tolls.

BBCI Company Secretary Winston Brassington said that the Highway Code will apply to the operation of the bridge and vehicles will be weighed.

Vehicle would be allowed to cross with up to 40 tonnes.

The company will hand over the bridge to the Government in 21 years.

Carter said when completed, the bridge will be the sixth longest floating bridge in the world at 1,570.719 metres.

He noted that the Demerara Harbour Bridge is the fourth longest of its kind in the world.

The bridge will be shorter than the Demerara Harbour Bridge and the width will be the same, about 22 feet.

The surface of the bridge is coated with an epoxy resin and then overlaid with calcined bauxite, making the bridge virtually skid free.

The bridge will be located downstream of the existing ferry route, starting from the village of D’Edward on the western bank to Crab Island on the eastern bank where the width of the crossing is 1.5 kilometres.

The MMA compound at Rosignol has been specially prepared for the site office, de-stuffing of containers, storage of bridge components, assembly of bridge spans and the pre-assembly or launching pad.

A generator building at D’Edward, the preliminary designs for the toll plaza, the operation and maintenance building and public facilities have also been completed.