When the above data are disaggregated, we find that Belize’s unit cost advantage lies in its field cost. This has averaged less than half that for Guyana. On the other hand, Guyana’s factory cost has been lower and far more competitive. As a rule, Guyana’s field costs have typically averaged about 62 per cent of the total unit cost of sugar production. Factory costs have averaged about 14 per cent, while ‘Other’ costs have accounted for the remaining 24 per cent. Fixed costs are high in Guyana; about two-thirds of total costs. As would be expected this places huge financial pressures on cash flow within the industry.

When the above data are disaggregated, we find that Belize’s unit cost advantage lies in its field cost. This has averaged less than half that for Guyana. On the other hand, Guyana’s factory cost has been lower and far more competitive. As a rule, Guyana’s field costs have typically averaged about 62 per cent of the total unit cost of sugar production. Factory costs have averaged about 14 per cent, while ‘Other’ costs have accounted for the remaining 24 per cent. Fixed costs are high in Guyana; about two-thirds of total costs. As would be expected this places huge financial pressures on cash flow within the industry.

GuySuCo

It is important for readers to recall that for a considerable period of this review of the sugar industry, it was privately-owned. The Guyana Sugar Corporation (GuySuCo) was formed in 1976, consequent to the nationalisation of the then Booker Sugar Estates (BSE) and the much smaller Jessel Holdings. After nationalisation, the expectation was that GuySuCo would operate as an independent commercial organisation, with the government appointing the Board of Directors. As matters turned out, however, whether through the government-appointed directors or by overriding them, the autonomy of GuySuCo as a commercial entity, independent of government hands-on involvement and micro-management has never ever been a reality. This circumstance doomed GuySuCo from the start, particularly as GuySuCo’s management reciprocated and naively in my view, embarked on a strategy of political manoeuvering and manipulation of the authorities in order to advance the corporation’s fortunes. This de-professionalisation of GuySuCo is one of its most emblematic traits.

This situation has led to enormous inefficiency, waste and corruption. It was no doubt, partly in an effort to reduce this outside leadership (which was clearly undermining the commercial autonomy of GuySuCo) that the government 14 years later, entered into a management contract with Booker Tate in 1990 to operate the then five sugar estates and eight factories located on the coast. This continued until recently, when amidst a great deal of acrimony, the management contract with Booker Tate was terminated.

This matter has been brought before the courts by both parties and is not yet settled. Clearly, a lot more discussion on all these circumstances needs to follow in regard to the issues of ownership, control, management and decision-making in the industry, as I continue to interrogate the current problems and prospects for GuySuCo and sugar production in Guyana. I shall embark on this in the coming weeks.

Revenue and expenditure

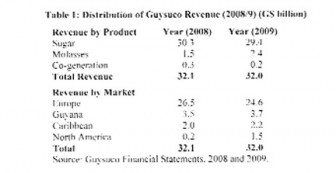

For the time being it should be observed that in recent years, based on the information presented in GuySuCo’s annual reports, the industry has been earning about $32 billion in revenue ― a considerable sum by any measure. Over 90 per cent of this revenue comes from sugar sales, with the remainder coming from two major by-products: molasses and the sale of co-generation electricity to the national grid. As has been already observed in these columns, the bulk of this revenue is earned in Europe (over 80 per cent) where the sugar is mainly sold, and the remainder in Guyana, the Caribbean and North America in that order. The table below summarizes these data, for readers’ convenience.

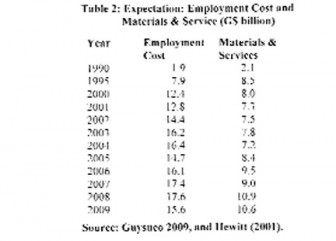

Turning next to expenditure, two substantial areas where GuySuCo spends its earnings are 1) employment costs and 2) material input costs and services. Data presented in GuySuCo’s reports on these expenditures, for the most recent decade (2000 to 2009) with comparative data for 1990 and 1995 are shown below.

From these data, the remarkable expansion in employment costs stands out. Whereas in the 1990s employment costs were lower than the costs of materials and services, over the 2000s the situation has been markedly reversed.

(Next week I shall continue from this point).