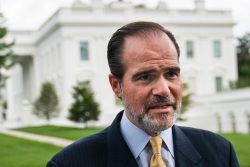

Somat Ali is not bothered in the least about the fact that his business enterprise is tucked away in the quiet East Coast Demerara village of Mon Repos, more than a mile from the public road.

Time was when potential customers fretted over their efforts to “find the place,” wondering, having gone past both the Guyana School of Agriculture and the National Agricultural Research Institute, whether there was an end to the Mon Repos public road. Eventually, they would see the landmark, an eye-catching collection of swings, slides and see-saws surrounded by a neat, freshly painted white fence. It serves both as a playground for the neighbourhood children and as a showroom for some of the products manufactured by Fibre Tech Industrial Plastics.

These days Fibre Tech has become a household name across the country, the profile of its products having been raised appreciably by the increased demand for fitted kitchens, fibreglass counter tops, lawn, patio and dining room furniture, bath tubs, jacuzzis and sinks. New homeowners are increasingly finding their way to Mon Repos to engage Ali on fitting and furnishing their homes to the taste and style they fancy. Other customers who had earlier acquired the company’s products are seeking refurbishment or – if you will – sprucing up of items which they had earlier acquired, a service which he says he provides “at a modest cost”.

In the 18 years since he re-migrated from Canada bringing with him both the skills and the business acumen acquired during years of running two separate fabrication enterprises in Scarborough, Somat Ali has become the country’s leading manufacturer in an industry that has been his preoccupation for 51 years. Currently, his assignments range from refurbishing items which Fibre Tech had previously installed at State House to render them suitable to the taste of its new occupants to supplying interior mining operations with portable bathrooms. Expansion plans at the factory site are under consideration though the current preoccupation is with the creation of a new, tasteful showroom closer to the East Coast highway; a project the commencement of which is awaiting state approval.

Fibre Tech’s pursuits go beyond simply manufacturing the products which it offers. “We work with our customers on issues of design, colour and fitting our pieces,” Ali says. Members of his staff have travelled both in and out of Guyana to ensure that their products meet customer requirements. As far as he is concerned the job is not quite done until whatever is supplied is fitted and begins to serve its purpose.

What sustains Fibre Tech, Ali says, is the premium which he places on customer satisfaction.

“The boast we make is that if the quality of one of our items falls below standard we will replace that item free of any additional cost to the customer. What that means, of course, is that we never undertake a job, no matter how big it is if we believe that at the end of the day we might be running the risk of compromising the reputation of our products. The nature of the products that we offer and the customer’s expectation in terms of durability and service means we must meet their expectations. That is why everything that we provide comes with a warranty.”

Having fitted “thousands of bath tubs and hundreds of kitchen sinks,” Ali says he will back his products against anything else that is on offer on the local market. “That includes products in the same range that are being imported.” He says he is not knocking the quality of the imported products but simply vouching for his own, though, from a consumer standpoint he wonders aloud as to why these imports are never attended by warranties. His concerns, he says, have to do with the likelihood that in some cases, imports cannot attract warranties because they may well be sub-standard products that cannot be marketed in their countries of origin. He believes a point has long been reached when the Bureau of Standards ought to be paying closer attention to the quality of some of the country’s imports as a means of protecting consumers. That way, he says, the significant additional cost associated with having high-priced appurtenances refitted – a job that he is currently undertaking for a local hotel that opted for imported fittings in the first place – can be avoided.

His second concern has to do with the impact of cheap imports on the local manufacturing sector. “Speaking for the manufacturing sector as a whole I am concerned that when you take account of the high costs associated with manufacturing here and the value-added tax we are simply unable to compete with goods produced much cheaper elsewhere and placed on the market at prices which our own production costs do not allow us to match. Of course, when goods are imported into Guyana at prices that are below their cost of production the state is robbed of revenue, local people are denied employment opportunities and consumers are short-changed,” Ali says.

While some consumers continue to favour imported items, Ali is satisfied that his own market share is growing. He believes the company’s growth is a function of its unwavering focus on satisfying the customer. “We give a commitment to doing over any of our product range that has a quality problem at no extra cost to the customer. That means, of course, that we have to begin by ensuring that everything that leaves our factory can perform to the standard that we set. A lot of the refurbishing work that we do today – not repairing but refurbishing – has to do with products that we originally installed around 1996.”

Beyond Fibre Tech’s on-site showroom at Mon Repos, the company has sealed deals with local business enterprises A Gafoor & Sons and A Ally & Sons of Berbice to market its products under the same warranty which it offers. “That means that we’re accountable unlike some importers who don’t want to take risks.” Beyond the marketing of its products through reputable local business houses, Fibre Tech is currently awaiting official permission for the construction of a new giant showroom at Mon Repos, close to the East Coast Highway.

Even setting aside the initiatives currently underway to consolidate its local market gains, Ali is satisfied that Fibre Tech Industries has made its mark. “There used to be a time when we would have salesmen going out into the field selling our products to potential customers. That has changed. People have come to know about us and our reputation and they are coming to us.”