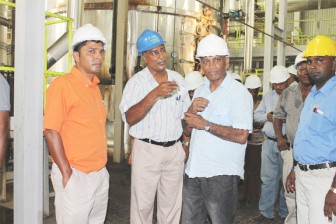

The flagship investment by the government has come in for criticism since its commissioning but Ramsammy noted during a visit to the facility yesterday that it is now demonstrating its potential despite challenges.

He said that from the perspective of the government and the management of the Guyana Sugar Corporation (GuySuCo), the factory is going to be one that will lead Guyana’s aspirations “to reach and exceed” a production level of 400,000 tonnes of sugar per year.

Ramsammy admitted it was true that the factory has had to undergo major rehabilitation, which was ongoing, but he was sure that innovations by the management of the factory will see further improvement in its potential.

He said the contract signed with South African firm Bosch Engineering is on stream and the company has already started its work, but not at the factory. The company is carrying out design work for the rehabilitation, which it is expected to carry out at Skeldon after this crop ends.

Recently, the Skeldon factory exceeded 2,500 tonnes of sugar for the first time and Ramsammy deemed this a remarkable achievement, since the output was more than twice what the old factory was capable of doing. Up to last Friday, he added, production had exceeded 13,000 tonnes of sugar for this current crop, for which the target is 27,000 tonnes. As a result, he said that this year’s target is likely to be surpassed.

“It means that for this crop we need about 14,000 tonnes more… so, if we meet that, we would not only surpass this crop target but also the annual target for Skeldon,” an optimistic Ramsammy stated.

“If we can produce about 2,000 per week it will give us 18,000 tonnes more at a minimum for the year, which means Skeldon is on target of surpassing the target,” he added, while noting that there are about 9 to 11 weeks more to go for the current crop.

Ramsammy added that the next milestone would be meeting an annual production target of 50,000 tonnes in the not so distant future, while saying that the annual target is likely to be increased to as much as 100,000 tonnes for the year 2016. ”So, for those who doubt, the proof of the pudding is in the eating… and so we are seeing it here,” he said.

‘Significant impact’

At a briefing after the tour of the factory, Ramsammy emphasised that the innovations by its staff have led to “some significant impact” on production.

He said that the original aspects of running the factory belonged to international experts but he noted yesterday that it is the local managers who have taken over absolute control and are making the changes that are necessary. “Guyana is too used of being critical of our own people,” Ramsammy said, adding that to be fair credit must also be given to locals.

Factory Manager Deodat Pertab said that the factory’s management decided to undertake an audit, after which it decided to take fix the problems in phases. Management implemented a maintenance programme and examined what the barriers are and how they are affecting production, he explained, adding that the programme involves the modification of processes within the factory itself, which include management of the boilers, evaporators and other machines. This, he noted, was done solely by the staff at the factory.

Meanwhile, it was noted yesterday that the cogent plant at the factory, which was intended to generate energy to the national grid, has provided a capacity of 11 megawatts.

Ramsammy said that the plant is to 90% of its capacity and next year this time, it is expected to surpass 20 megawatts. He explained that the plant currently depends on steam generated from bagasse, which means that less heavy fuel oil (HFO) will be used—a move which will reduce costs. He added that some of the operational elements of the factory are saving money that could be channelled to other innovations of the factory.

The US$200 million Skeldon factory was built by the China National Technical Industrial Corporation (CNTIC) as a flagship project aimed at boosting sugar production past the 300,000 tonnes mark annually. It has, however, experienced major problems ever since it was commissioned in 2009.

It has also been affected by the impact of the rains on the cane fields, which has severely hampered production there. In April this year, GuySuCo announced that the factory was set to undergo major rehabilitation in order to have it fully operational. This included the redesigning and re-engineering of several aspects of the facility, on which GuySuCo has been working with the Bosch Group of Companies.