At the age of 15, Satrohan Sookdeo was required by his father to end his formal schooling and seek an apprenticeship in a trade that might one day provide him with a regular income. He does not clearly remember the sequence of events that took him to Berbice and into the highly specialised trade of boat-building. Upon reflection, however, he is in no doubt that his choice of trade was an inspired one. He believes that he has done well.

It took Sookdeo, better known as ‘Sat’ five years to learn to build boats, during which time he subsisted on a modest stipend. It was, he says, a painstaking learning process in which there was little if any room for error. For obvious reasons considerations of safety and durability cannot be compromised.

His particular specialisation is cabin cruisers: fishing vessels comprising four modest compartments for sleeping, storing ice, fish and seine. The steady growth of the fishing industry has witnessed the expansion of his own enterprise which is located on the Mon Repos access road.

A fishing vessel, Sat says, can range in price from $600,000 to $2.8 million depending on the size-related requirements. However, each boat must be built to the same high standard. In this particular industry, the price of slipshod work could be high. More than that, in such a high-risk industry, customers demand warranties. Sat says his warranties, which cover repairs, could extend for as much as a year.

Cabin cruisers are made of greenheart, mora and silverballi and Sat makes the point that nothing else would do. “These things spend all their lives on water,” he says. It takes four workers around six weeks to build a vessel, in good weather, that is. If the weather is bad it takes longer. Boat-building is “an outdoor job.”

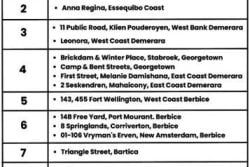

The market is dictated by logistics. Sat’s customers come from the East Coast, West Coast, East Bank and Georgetown where the fishing trade continues to thrive. He is entirely satisfied that at Mon Repos he is strategically well positioned to secure a fair share of the market.

His concern with quality and safety means that he must take responsibility for the critical aspects of the job; like purchasing timber. Adjustments in the behaviour of the timber after the pieces are put together to comprise a boat could spell disaster.

Sat is aware of the complexities of the timber trade including the likelihood that a less experienced buyer may not secure the best material for the job. Sat says it is not uncommon for prices to be inflated once some dealers become aware that purchases are being made for boat-building.

Some customers exercise the precaution of providing their own material though the interaction between craftsman and customer often goes beyond the subject of timber. Sat explains that the discussions often extend into details like type of catch for which the boat will be used.

Boats used for catching larger fishes like trout or snapper must have greater storage capacity. A boat built typically for larger fish can measure 52 feet x 9 feet.

Boats built for smaller fish can measure 45 feet by 8 feet. Sat explains that the larger vessels usually spend about two consecutive weeks at sea while the smaller vessels “go fishing” for three to five days at a time.

Sat explains that the cost associated with building a boat is largely a function of the amount of timber that is wasted on account of the nature of the trade. He explains that out of the 4,000 board metres of timber acquired to build a boat as much as 1,000 board metres could be lost to “carving and shaping”. What is left is given away for use as firewood.

Sat says that during the course of construction he may receive several visits from his client. Once construction is in progress there is usually a degree of concern that the job gets done properly.

Already highly proficient in his trade, Sat has set himself the goal of making a protracted contribution to the fishing industry by building sturdier, more efficient vessels. He is concerned, he says, about the product quality challenges in the timber industry.

These days timber must be bought and dried before it can be applied to the building of a vessel. The weather, too, is often a concern. Sat does not recommend that boats be built indoors.

The job completed, the boat is loaded onto a tractor and trailer, driven a short distance across the East Coast Demerara public road, hoisted over the sea wall, across an expanse of beach where it is met by the owner and captain. The handing over and familiarisation process completed, Sat’s job is done and the boat sets out for its destination.

Hopefully, it will be some time before he sees it again, for routine maintenance.