The “Rice Brekkies” cereal, launched at last week’s GuyExpo by President Donald Ramotar, is a pilot project developed by the Institute of Applied Sciences and Technology (IAST) and the factory still has to be set up and the product cleared by the regulatory authorities.

The project is being commercialised due to the effort of the Minister of Commerce Irfaan Ali, who saw the potential of the product and its relevance in the Guyana context, during a visit by the Minister and the President Ramotar to IAST earlier this year.

The cereal, which is pending approval from the government’s Food and Drug Department, is currently manufactured at the IAST’s facilities at Turkeyen, at a pilot scale which is approximately 600 250g boxes per week.

Through the collaboration of the Ministry and the IAST, funding for the construction of a manufacturing plant was procured from the Rural Develop-ment Fund, administered by the Ministry of Tourism, Industry and Commerce. The capital cost is anticipated to be $75 Million. The institute would be responsible for supervising the building and commissioning of the plant as well as training staff, developing quality control measures and overseeing the operation of the plant over the initial years of its operations.

Speaking to Stabroek News on Wednesday, Director of the IAST Professor Suresh Narine said that the plant will most likely be located at Anna Regina, in Region Two. The exact location was expected to be announced later in the week. He also anticipated that the plant would take four to six months to be completed. The IAST has already completed the full design and is ready to begin the tendering process. Narine said that from the promise of the return on investment from the cereals project, which the institute has calculated to be 27% to 33%, the initial investment by government in the institute’s efforts has been vindicated.

When asked about the type of technology used in the manufacturing process, Narine explained that the process of extrusion will be used. Extrusion is a way of cooking which applies controlled torque and heat to food products. It is also the same process used to produce textured vegetable protein, such as soy chunks.

Narine noted that in 2013, the IAST had acquired a pilot scale food and pharmaceutical extruder, an instrument which was entirely funded by the Government of Guyana. This instrument cost $55,582,785. He also recalled that the level of scrutiny from cabinet members was significant because the cost of the equipment was high. However, the institute was able to convince cabinet members that the application of extrusion technology to many of the agricultural commodities would result in creation of a number of high-value products.

This multi-functional extruder acquired by the institute, he said, has allowed many staff scientists to develop a variety of products already, including risotto,

Thai noodles, vermicelli noodles and glass noodles. Other products, such as a composite chip made from plantains, breadfruits and cassava, are under development. The same equipment will be used to develop a nutritionally balanced aqua-culture feed, which provides superior floatation to imported feeds. Although the institute is proceeding first with the “Rice Brekkies” cereal, it expects to be focusing in 2015 and beyond on the commercialization of a host of value-added extruded products.

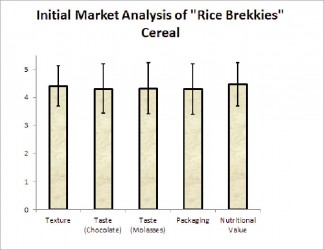

Narine related that the market research, which had been carried out at GuyExpo, rated the rice product high and the Institute handed out some 3,000 samples of the two flavours of cereal at their booth, both for tasting and as “take-homes.”

He reported that 524 members of the public completed their evaluation form, which graded the texture, taste, nutritional value (the consumer’s assessment based on the label) and packaging. He then said that 90.6% of the respondents indicated that they would purchase the cereal at current market prices for imported cereal.

Although the professor was hesitant to say what the final cost of the 250g box of cereal would be, he said that the price would be equivalent or, less than the cost of imported cereals with similar nutritional values.

He also said that IAST and the Ministry are working closely with a branding company to ensure that the packaging of the product is comparable to international standards. He also stated that given the increased productivity in the rice sector, he feels that sustainability of the venture is very secure from a raw materials perspective.

There has been increasing pressure on rice industry stakeholders to find value-added uses for rice, given the large crops grown recently and the difficulty in finding new markets.

Minister of Agriculture Dr Leslie Ramsammy told the Government Informa-tion Agency (GINA) that the launch of the rice cereal represented the very essence of transformation and added that the government and people of Guyana are moving away from just producing raw material. “We have embraced the concept of the value chain and adding value to what we produce. Guyana has always been known as a producer of good rice and we will continue to do that, adding different types of rice,” Ramsammy was quoted as saying.

He further explained that the rice cereal would be fortified with additional vitamins and micro-nutrients in the near future and added that it is another example of the transformation in Guyana. “We will also be using rice products, rice husk and so on will be transformed into energy and stock feed. Every part of an agriculture product will be utilised, we are transforming from where the rice industry not only produces rice, but waste into 100% meaningful and useful profitable products,” he noted.