A new well at Port Mourant, Berbice, Region 6 to the tune of $60M will increase the production capacity needed to serve surrounding communities for 24 hours, the Guyana Water Inc said yesterday in a press release.

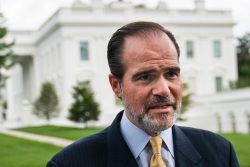

During a tour of the well site by GWI’s Managing Director and other officials on Friday, Executive Director of Planning Implementation and Project Building, Ramchand Jailal said that the well, which is being drilled by Trinidadian Company Water and Oil, has reached its required depth of 1100 feet.

According to GWI, Jailal noted that to date, samples have been taken and “We are trying to improve the capacity of this Port Mourant plant because currently we have the wells that are serving this plant, the Williamsburg well is down and the well within this plant has a structural challenge right now so it’s not pumping to its full capacity.”

GWI said that the construction of the current well is part of an emergency plan, since the two wells serving the communities have encountered challenges in producing – the Williamsburg well suffered a breach in its well casing, while the Port Mourant well experienced a structural failure.

The plan therefore, is to ensure the new well delivers within the next month. “When this well is completed and tested, we will put the water to the plant…right now the residents within the communities that receive water from the project area, they receive water 4 hours in the morning, 4 hours in the afternoon. We are working to achieve a 24 hr supply”, Jailal stated.

Jailal added, “When we complete the well and test the well, we will know the production and we will then be able to determine if we can supply 24 hours or if we still have to drill another well. The target is trying to get to 24 hrs. We are hoping with the calculation we have done, that we can be able to achieve at least 20 hours right now with the completion of this well.”

GWI’s Managing Director, Dr. Richard Van West-Charles said that following this project, GWI will have a better knowledge of the best materials suited for well drilling on the coast. “There are so many examples because of the salt air and the salt on the ground so to avoid the corrosion, we’ve seen along the coast, I think it is right at this time that GWI will define very clearly, what are the best materials to be used that are durable”, he stated.

“There will be no guesswork. We have 18 wells with carbon steel casing which have corroded. There is the well at Hope which is in a bad way also Vergenoegen. There are different parts we have to look at and that is because clearly we did not select and identify the right materials to be used. There is a lot of rusting that has gone on and we now have to arrest that and move forward in a more structured manner” the Managing Director said.

GWI is also looking to upgrade the well at Fyrish as a priority. Dr. Van West-Charles said the well there is aged and under pressure to produce. The company is therefore looking into drilling a new well there.