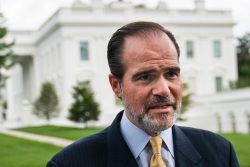

When you tell Michael Nunes that agro processing has become one of the fastest growing sub-sectors in Guyana’s agricultural sector and that modest quantities of locally manufactured products are beginning to find their way onto external markets, the nonplussed expression on his small, chiseled face does not change one iota. “The industry needs help,” he says. “We need institutions that can support us financially and technically. Agro processing is an opportunity for the small man, and we need help.” It is as if, having secured an opportunity to engage the media on the subject he is desperate to ensure that the message reaches the right ears.

At 62, the diminutive Rastafarian can still remember a time more than half a century ago when ‘bush tea’ was the staple beverage in his mother’s home, the exception being Sundays when she ‘spoilt’ the family with cups of hot chocolate, the fat sitting atop the steaming liquid. These days, he makes a living with the ‘inheritance’ his mother left him. Besides the cashew nuts and pineapples which he cultivates at Kairuni on the Soesdyke/Linden Highway, his other crops include some of those same ‘herbs,’ that his mother brewed all those years ago. Only these days the herbs are gathered and dried and afterwards packaged as leaves or bark and offered with their printed recommendations as ‘remedies’ for an array of ailments ranging from backaches to diabetes. The herbs, Sage, Teasum, Lemon Grass, and Sarsaparilla are sun-dried (while the Kapadulla bark is purchased from Amerindian farmers) and stored. Afterwards, Michael packages these and markets them as beverages, the packaging providing details of the particular health benefits that each herb brings.

His beverages apart, Michael also manufactures a liquid, wine he says, exotically named ‘Da Real Roots Tonic.’ It is a mixture of capadulla bark, sarsaparilla, Double Doer Bark, pineapple, brown sugar, cinnamon, nutmeg, clove, vanilla and yeast and the label on the bottle simply says ‘rejuvenating, reinvigorating.’ Marketing of Michael’s products has piggy-backed on the historic local popularity of bush remedies though, these days he is targeting a more sophisticated market that includes the ‘up market’ supermarkets and those expanded markets in the region and in North America and Europe where there is still a significant appreciation of the virtues of Guyanese ‘bush’ remedies.

Like the scores of other agro processors who came before him he uses the Guyana Marketing Corporation’s Guyana Shop as a sort of incubator. It is here that both his product and its packaging will come under critical scrutiny and before that what he has to offer must get the blessings of the Government Analyst Food and Drug Department (GA-FDD).

His experience of the public/private sector-organized UNCAPPED events late last year and earlier this year has imbued him with a sense of the distance that the brand which he calls Da Real Products still has to travel. Those events have thrown him into the furnace of competition and now, he says, he wants to effect a complete operating makeover beginning with the cultivation, harvesting and storage of his raw material.

Michael concedes that it is the evolution in product refinement that has unfolded in the agro-processing sector in recent years that has caused him to cultivate an enhanced understanding of the need to take his own products ‘to the next level.’ His packaging, he says, is “not perfect” but at least the improvement is reflective of an understanding of the direction in which he has to go.

Further product refinement remains a challenge. The process of desiccation of the herbs and afterwards their crushing into powder to manufacture tea bags requires machinery that is beyond the means of small-scale agro-processors. Nunes believes that these are affordable investments for government but that they can change the lives of a great many ordinary people. “Ordinary people are willing to help themselves but they need the push which the government can offer,” he says.

It is here, he says, that the rubber hits the road.

“The majority of people doing agro-processing are operating manually and on a small scale. They cannot afford to go bigger. If we are to compete we need the kind of help which only the government can offer. We need the finances to support the purchase of the kinds of machinery that will help us with production.” He does not believe that the Small Business Bureau, on its own, can respond adequately to the challenge.

The extent of the grants being offered by the Small Business Bureau, $300,000, is insufficient in most instances to finance the level of investment needed to put even a modest agro-processing operation ‘on its feet’. Michael is currently engaging the Bureau but when you ask him about the support that he anticipates and whether it can meet his expansion needs his phlegmatic response is that “we need a much more ambitious effort to solve this problem”. The “problem” of which he speaks is the more than 20% of the beneficiaries from the Bureau’s grants whom, up until now, have realized no meaningful breakthrough. “If the support that the sector wants does not come we will continue to have that problem,” he says.