Australian gold miner Troy Resources has accepted responsibility and has agreed to pay the $1 million fine for the recent fuel spill at its Karouni, Region Eight worksite.

It is working with the Environmental Protection Agency (EPA) to ensure that there is no recurrence and that all required safety measures are in place.

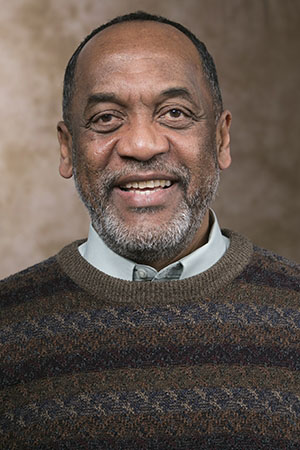

“Yes, the story is accurate and we did receive a reply from the company the very afternoon the letter was sent to them. They responded and accepted responsibility and they accepted their liability,” EPA Executive Director Dr Vincent Adams told Stabroek News yesterday, when contacted.

Stabroek News reported on Sunday that Troy Resources was fined $1 million by the EPA for the spillage of some 5,000 litres of fuel at its Karouni worksite and it has been ordered to pause works to emphasise safety measures.

Stabroek News reported on Sunday that Troy Resources was fined $1 million by the EPA for the spillage of some 5,000 litres of fuel at its Karouni worksite and it has been ordered to pause works to emphasise safety measures.

“They agreed to pay the fine. They submitted, by email, some of the information we requested. We haven’t reviewed it but they are cooperating fully,” Adams told Stabroek News. And while the recent social distancing guidelines at the agency in light of the novel coronavirus disease (COVID-19) pandemic has made it unable to visit the Region Eight operations, it will do so as soon as restrictions are lifted, Adams said.

In its letter informing of the $1 million fine, the EPA told Troy it believed that the incident could have been avoided had certain safety measures been taken and scolded the company for what it believes was an accident that endangered the lives of its employees.

Adams said yesterday that the strongly-worded letter reflects how the agency feels about safety. He said that while Troy has to be given credit for their cooperation and timely responses to the agency, it has to address the issue of safety.

“The company seems willing to cooperate and that is a good thing and I have no doubt we will get everything stated. But I have said publicly and cannot emphasise enough that safety is about a culture. It is not about describing that we have to do this or we have to do that and having manuals to read and all of that; it is a culture. We have to make sure that everybody that leaves home for work in the morning goes home the same way or better learned about safety measures. It just have to be a culture thing,” he said.

“If something is not right, not just at Troy but every worksite, then every single worker should have the right to raise a red flag or shut off work,” he added.

Bypass

As it pertains to Troy, Adams said that the EPA told the company how it felt. “In order to restart, they obviously had to make many safety checks and walk downs. That was a must before commencement. And yet here you are saying all safety systems are in place and a simple but hazardous activity in the transfer of fuel is allowed to bypass everyone. Two safety systems were non-functional; the full tank actuator and the valve. This is routine activity and the very routine inspection should have picked that up.

“Here you have a valve that leads the material to run to the ground and they did not even know how long it was missing? You cannot tell me that after so many workers are passing there every day, they did not see that missing. That is what worries the EPA more than anything else, and it begs us to ask what else is there that they are not seeing? What are the other precursors that are staring them in the face and they are not seeing that could possibly result in injury or death and/or harm the environment? This is very similar to the issue we had with Repsol. It was a simple valve situation…it is simple things that cause environmental upsets and even the death of workers. So there has to be a culture where safety trumps production. Where safety is a priority. That has to be the mantra of every single facility. Safety has to [have] priority over production,” he emphasised.

The EPA had noted that it was the company which provided information about the spill to the agency through a letter dated March 23rd 2020. As part of the requirement for a permit, persons/organisations have to sign that they will report all accidents and environmental hazards.

The EPA surmised in its letter that “Fuel was being transferred via a transfer line to a fuel storage tank housed in secondary containment. The full-marked automatic shut-off actuator was non-functional, resulting in the overflow of fuel into the secondary containment; but the valve connecting the secondary containment to the discharge pipe, was removed some time in the past, causing the secondary containment to overflow the 5000 liters of fuel directly onto and into the ground.”

The agency expressed concern over the incident and pointed to a fatality at the site last year.

“On account of the above summary description of the incident…and considering the safety track record of the operations resulting in a recent fatality at this particular site, the agency is highly troubled that there seems to still exist a conduct of operations culture at the site that is neglectful of the safety and health of the workers, and protection of the environment…” the EPA wrote.