As the novel coronavirus pandemic continues to wreak havoc worldwide, local attorney and photographer Nikhil Ramkarran has turned his skills towards producing facial shields for frontline doctors fighting the disease.

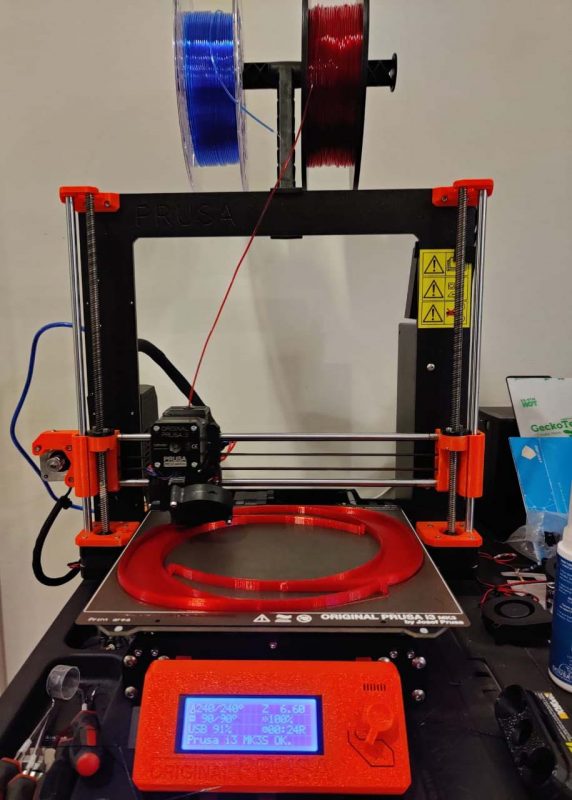

Ramkarran, like many others around the world, used his 3D printing machine to make the shields.

“I was just happy I can do something to feel useful… Everybody is stuck at home not really doing anything much. It is nice I can be of use to somebody,” Ramkarran told Stabroek Weekend about making the reusable shields.

Describing 3D printing as “a hobbyist thing for me,” Ramkarran said he noticed a lot of communities around the world were producing the shields and face masks for their medical frontline workers in the Covid-19 fight and he thought it was “a fantastic idea”.

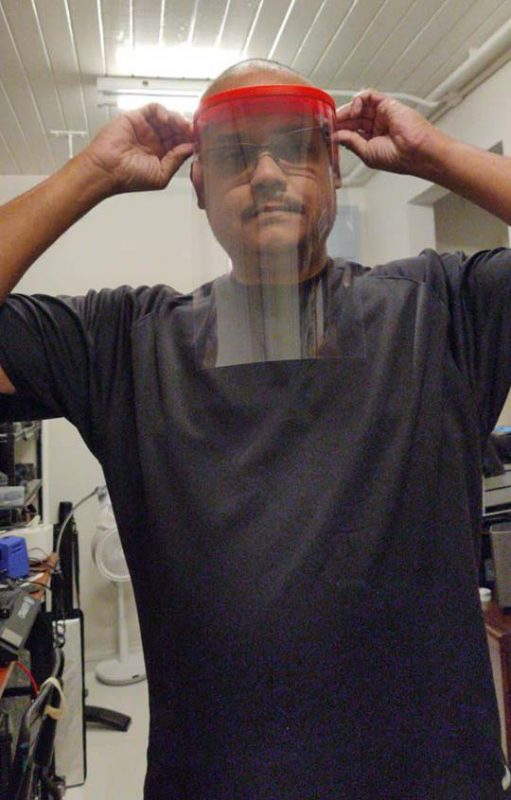

He explained that to make the shields there is a component that needs to be bought and that is the clear plastic. He used plastic that is commonly used on the front of education-based assignments, which he was able to pick up at stationary stores. These cost just about $100 each.

The frame is what is printed by the 3D machine. He made 100 of the shields which he donated to doctors at the Georgetown Public Hospital and the doctor with whom he liaised indicated that they have enough.

Ramkarran is now making shields for those who request them individually and he shared that he has made one for a friend’s brother who is a doctor and another friend whose son is a dentist.

“People have asked, and I am happy to be providing,” he said. “Now that I have gotten the doctors out of the way I am doing one and two more for the family, a few people have asked and I have the stuff and it is not a big deal to do it,” he continued.

‘The story’

Chronicling the journey to making the shields on her Facebook page, Ede Tyrell shared that it was Ramkarran who first mentioned that he was planning to make masks for his family using the 3D printer and at that time she was unaware this could be done.

Later, another friend sent her a link about ‘Jamaicans Build Emergency Ventilator and 3D Face Shields’.

She made a suggestion in a WhatsApp group about it being done in Guyana and “immediately, Nik [Ramkarran] responded that he could print the shields”. A discussion followed and Ramkarran revealed that he had the materials to print the attachment part and he would enquire about the transparent plastic.

She contacted a friend, who is part of the Covid Unit, to liaise with Ramkarran as they needed to know if the shields would be useful and effective. A few different designs were made and given to the doctor to test with his team.

Ramkarran later made 100 face shields, which were donated free of cost.

“I asked these gentlemen to give me permission to tell this story, and you would not believe how I had to beg, cajole, steam roll and eventually look them ‘virtually’ in their eyes and lie – and say that I would make the post all about me, and how amazing I am, and I’m the glue and I would just mention them in passing in two sentences – just to get them to agree to let me tell this story,” Tyrell said that while some were spewing negativity on Facebook, “bickering and waxing philosophical about what they perceive to be important, there are other men who are working together to get tangible things done – not for themselves but for the benefit of others. And doing it without blasting videos and photos of themselves on Facebook.”

3D printing or additive manufacturing is a process of making three dimensional solid objects from a digital file. The creation of a 3D printed object is achieved using additive processes. In an additive process an object is created by laying down successive layers of material until the object is created. Each of these layers can be seen as a thinly sliced horizontal cross-section of the eventual object. The printing is the opposite of subtractive manufacturing which is cutting out/hollowing out a piece of metal or plastic with for instance a milling machine. It enables you to produce complex shapes using less material than traditional manufacturing methods.