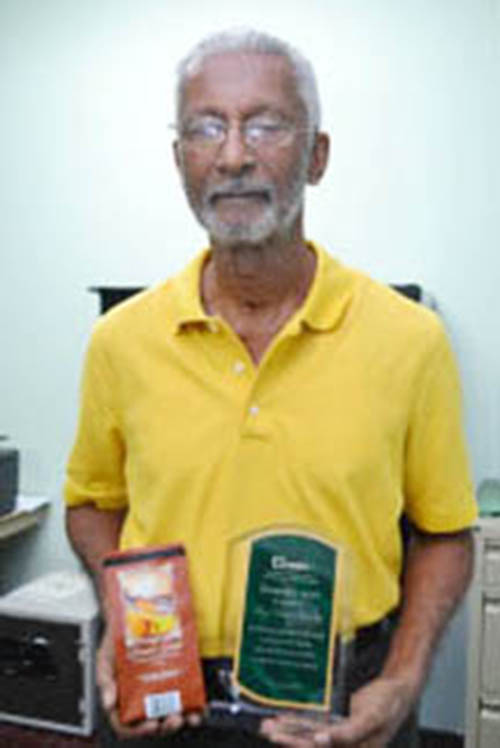

Even as the coffee manufacturer, Amy’s Pomeroon Foods Inc (APFI) continues, along with other local agro-processors, to feel the economic squeeze associated with a weak domestic market, and latterly, the wider economic impact of the coronavirus pandemic, the company’s chief executive officer, Louis Holder, has outlined to this newspaper a series of measures which he believes can grow local businesses and “keep Guyanese employed and the economy resilient.”

At the top of Holder’s list of recommendations is the passage of legislation that sees the creation of a “Buy Guyanese Act,” which is “similar to the Buy American Act of 1933” that will allow for “government procurement funds” to be used “only to buy local goods and services,” once these are available.

The US Buy American Act applies to government agency purchases of goods valued over the “micro-purchase threshold” though it does not apply to services. Under the Act all goods for public use must be produced in the US, and manufactured items must be manufactured in the US from US materials. The Act creates a “price preference” that favours “domestic end products” from US firms.

While the enactment of similar legislation here could encounter pushback from both businesses and consumers, on the grounds that it curtails choice, Holder believes that the growth of local businesses and by extension, growth in the country’s economy, can only be realised if market access conditions are more favourable for local goods and services.

Holder is also advocating the application of “Local Content Laws” that go beyond oil and gas and extend to “all foreign companies operating in Guyana. Specifically, he named the mining and timber industries as sectors to which such Local Content laws should apply.

The local businessman also wants to see the coming into force of laws that require all multinational distributors operating in Guyana to “carry local products and distribute those in other Caribbean markets in which they operate.” Finally, Holder wants to see regulations that require local retail outlets to “give the same level of shelf space and prominence to local products as they give to foreign substitutes.”

While Holder points out that these recommendations “would have no impact on government budgets but go a long way towards creating and sustaining employment in the Guyanese economy,” it is not difficult to see where some of them could encounter charges of protectionism from both the big-spending high profile brands that spend much more on attracting consumer attention as well as consumers who may push against initiatives that limit choice, Holder has been a long-standing advocate of initiatives that expand market access for local products.

Holder says however, that what he describes as “buy local” measures, will have a significant positive impact on the performance and viability of local manufacturers, apart from which he says, APFI is in the process of taking “additional measures” that will have a “significant bearing on its viability.” These measures, he says, include initiatives that will result in the realisation of new products to its present product line which include the introduction of a “chocolate bar, breakfast spread and coconut-milk powder.”

API acquires its coffee beans from the Pomeroon-based Nova Zeelandiaan, described by Holder as an “Associate Company” and which, he says, purchases coffee berries from “over twenty farmers in the Region.” Processing involves “an upstream 5-step processing, referred to in the industry as a wet process” that incorporates washing the berries, pulping that removes the outer bean covering, fermenting to remove a mucilage covering the parchment, drying, and finally, hulling, which results in the removal of a shell covering the bean. Using this process, the manufacturer is able to realise higher quality, better tasting coffee, albeit at a higher cost.

At its Georgetown factory, the green beans are roasted, ground and packaged using state-of-the-art equipment. The company’s Turkish-made roaster is equipped with computerised capabilities to ensure consistent profiles.