With the recently repaired flash gas compression system on the Liza Destiny oil platform still experiencing some technical issues, ExxonMobil said it is now flaring about six million cubic feet of gas per day.

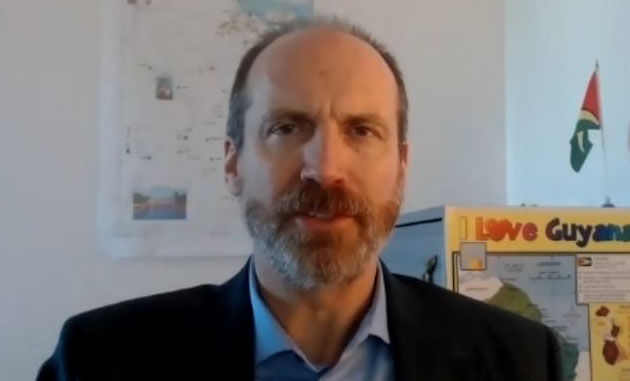

Production Manager of ExxonMobil’s local affiliate, Esso Exploration Production Guyana Limited (EEPGL) Mike Ryan said that while the repaired and upgraded compression system is operational on the Liza Destiny Floating, Production, Storage and Offloading (FPSO) oil platform, they have been unable to reduce flaring to pilot levels.

In a video released by Exxon, Ryan disclosed that after completing phase one and phase two testing along with an endurance run, they found that there is still some amount of axial vibration in the third stage gas compressor. He noted that the vibration was causing damage to the compressor, which resulted in it being sent for repairs in Germany several times.

Faced with a repetition of those issues, he said, the team on Liza Destiny is focusing on trying to find the right level of operation for the compressor so that the vibration can be minimized, thereby keeping the machine in operation and at the same time, minimizing flare levels.

According to Ryan, the gas compression and injection system is in place to help to manage the fluids from the oil reservoir and he added that when the fluid is transported to the FPSO from the reservoir, the compression system separates the oil and gas, and then re-injects the gas into the reservoir.

Prior to the flash gas compressor coming online, he said, about 88 to 90 percent of the gas was being re-injected and consumed but with the compressor re-installed they are now re-injecting about 96 percent. “While we are not all the way there, we have made significant improvements in reducing gas being flared,” he said.

He subsequently added that the team continues to work extremely hard with technical experts with their number one objective being how to operate the current design of the compression system while protecting it, and minimize flaring.

“Because of our current operating mode, we are flaring in the rage of 6 million cubic feet per day,” he disclosed. Prior to the re-installation of the compression system, flaring was ongoing daily offshore at some 16 million cubic feet of gas per day.

In a statement on Friday, Exxon had said that the team continues to perform maintenance and optimization activities on the compressor with the aim of keeping the flash gas compressor online and minimizing flaring until the arrival of the new flash gas compressor at the end of the year.

Ryan said that they are maintaining oil production between 120,000 to 125,000 barrels of oil per day (bpd) to keep the compression system stable but are exploring ways which will allow them to further reduce flare levels and inject more gas. He noted that lowering oil production will not affect flare levels and stated that Exxon is working with the government to create a balance. He added that their combined priority is to keep people safe, minimizing environmental impact and maximizing the benefit to Guyana.

With more FPSOs expected to come online in Guyana in the coming years, Ryan said, there has been a dedicated focus on the issues that have arisen on the Liza Destiny to ensure that lessons are learnt and that future FPSOs do not encounter the same issues.

Since January this year, ExxonMobil has experienced major problems with the gas compression equipment on Liza Destiny and this has led to environmentally-damaging gas flaring.

President of ExxonMobil Guyana Alistair Routledge had said that the gas compressor failed in the middle of the night on January 27 this year, when optimisation testing was ongoing and the production level was around 130,000 bpd. However, he maintained that this was not in any way linked to the malfunction.

Ryan outlined that the compressor had a number of issues throughout the months but the team has addressed them systematically. He noted that there was an issue with the discharge silencer but this was repaired and upgraded. A venturi was also installed.

Following the malfunction, the gas compressor and other key parts were sent to Germany for repairs. A few weeks later, it was announced that logistics for its departure from Germany were being finalised following the successful completion of repairs, upgrades and mechanical testing of the compressor by MAN Energy Solutions, the equipment’s manufacturer, with quality assurance and control by experts from the vessel’s owner SBM Offshore as well as Exxon.

On April 13, ExxonMobil announced that its third phase of testing of the repaired gas compression equipment on the Liza Destiny had failed and that this had resulted in production being slashed to 30,000 barrels. However, several days later the Company said that it had begun ramping up output and that a solution was at least three months away during which controversial flaring would occur. The gas compressor was sent to Houston, Texas in the United States for repairs.

With the compressor having had to be repaired twice during the early part of this year, the Environmental Protection Agency (EPA), modified the Environmental Permit for the Liza Phase 1 Development Project, mandating EEPGL to pay for gas flaring once it continues beyond a 14-day period. Last month Exxon had submitted an application to the EPA seeking its approval to flare beyond pilot levels, in an effort to facilitate the continued testing of a discharge silencer.