-60-day review process underway

An environmental study was yesterday submitted by ExxonMobil’s subsidiary to the EPA for a US$1.3b gas to shore project which the government hopes will lead to vastly lower energy costs that would enable a spurt in manufacturing but doubts have persisted over execution capacity and whether a real feasibility study has been done.

Critics have argued that as with oil extraction in the Atlantic, the government intends to plough ahead with converting gas to energy no matter what and that it has sway over the regulatory authorities who will have to grant permission for the project on the West Bank Demerara to proceed.

The Environmental Protection Agency (EPA) yesterday announced that ExxonMobil’s subsidiary Esso Exploration and Production Limited (EEPGL) has submitted its Environmental Impact Assessment (EIA) for the much-touted gas to energy project, thus triggering the 60-days public review process.

In a notice to the public, published in yesterday’s Stabroek News, the EPA said “…the Environmental Impact Assessment (EIA) and Environmental Impact Statement (EIS) for the proposed Esso Exploration and Production Limited’s (EEPGL) Gas to Energy Project, to be located within both the offshore Stabroek Block as well as onshore Guyana, have been submitted to the Environmental Protection Agency (EPA).

In a notice to the public, published in yesterday’s Stabroek News, the EPA said “…the Environmental Impact Assessment (EIA) and Environmental Impact Statement (EIS) for the proposed Esso Exploration and Production Limited’s (EEPGL) Gas to Energy Project, to be located within both the offshore Stabroek Block as well as onshore Guyana, have been submitted to the Environmental Protection Agency (EPA).

“In accordance with Section 11 (10) of the Environmental Protection Act, Cap. 20:05, members of the public are hereby invited, within sixty (60) days from the date of publication of this Notice, to review said EIA/EIS and make written submissions to the Environmental Protection Agency, as they consider appropriate.”

“In accordance with Section 11 (10) of the Environmental Protection Act, Cap. 20:05, members of the public are hereby invited, within sixty (60) days from the date of publication of this Notice, to review said EIA/EIS and make written submissions to the Environmental Protection Agency, as they consider appropriate.”

All submissions are to be addressed to the Executive Director of the EPA and sent to the Ganges Street, Sophia office or emailed to epa@epaguyana.org while the EIA is available on the Agency’s website, the National Library and the Regional Democratic Councils throughout the ten Administrative Regions.

EEPGL filed its application for environmental authorization in early 2021 which was subsequently amended. Following a review by the EPA, it was decided that an EIA would be required before the project moved ahead. That process commenced with public engagement on the scope of the study as well as the proposed terms of reference.

On September 21, 2021, the EPA approved the final terms and scope for the EIA after which EEPGL was tasked with hiring a qualified independent environmental consultant to conduct the EIA for the project. The terms for the EIA were not published. The EPA, in accordance with the EP Act, approved Environmental Resources Management (ERM) as the executor of the study.

ERM has controversially been the company conducting all of EEGPL’s environmental studies and several questions were raised about their independence and autonomy in the process. Those questions have not been addressed by EEPGL, ERM or the EPA.

ERM says that the study was prepared in association with the Guyanese consultancies E&A Con-sultants, Inc. (E&A), Caribbean Engineering & Management Consultants Inc. (CEMCO), the Uni-versity of Guyana Centre for the Study of Biological Diversity (CSBD), and Leon Moore Nature Experience (LMNE); Trinidadian consultant Caribbean Transportation Consultancy Services Company Limited (CARITRANS); and U.S.-based consultant SLR International Corporation (SLR).

It added that the purpose of the EIA is to provide the “factual and technical basis” required by the EPA to make an informed decision on EEPGL’s Application for Environmental Authorisation for the project.

ERM and its associates say that the project activities are predicted to have negligible to moderate impacts on physical resources, negligible to moderate impacts on biological resources, and negligible to moderate impacts on socioeconomic resources—with a number of positive impacts on socioeconomic conditions.

The EIA states that the project will use the associated natural gas produced from the Liza field in the Stabroek Block and the government of Guyana is pursuing a separate project to construct a power plant that would use a portion of this associated natural gas as a fuel source. It noted that it is at the government’s request that EEPGL is proposing the project to provide fuel for the power plant.

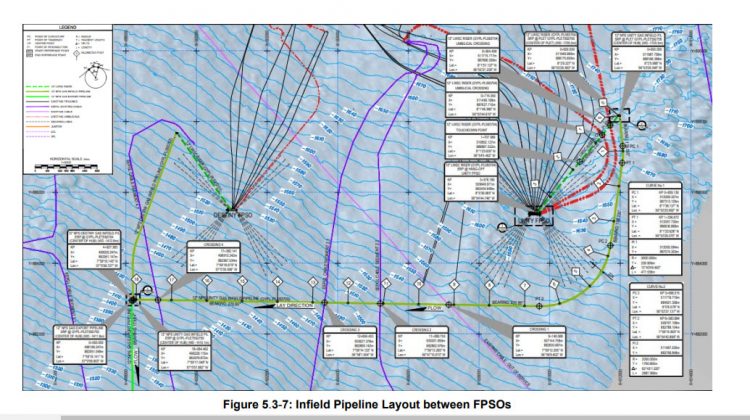

EEPGL said that the project will involve capturing associated gas produced from crude oil production operations on the Liza Phase 1 (Destiny) and Liza Phase 2 (Unity) Floating, Production, Storage, and Offloading (FPSO) vessels, transporting approximately 50 million standard cubic feet per day (MMscfd; 1.4 million standard cubic meters per day [MMsm3/d]) of rich gas via a subsea pipeline and then an onshore pipeline to a natural gas liquids (NGL) processing plant (NGL Plant), treating the gas to remove NGLs for sale to third parties, and ultimately delivering dry gas meeting government specifications for use at the Power Plant.

The project includes the construction and operation of a natural gas pipeline from the Liza Phase 1 (Destiny) and Liza Phase 2 (Unity) FPSO vessels via a subsea and then onshore natural gas pipeline to an onshore NGL Plant. The pipeline will transport up to approximately 50 MMscfd of dry gas to the NGL Plant. The NGL Plant will drop the pressure of the gas; dehydrate the gas; separate out the NGLs (i.e., propane, butane, and pentanes+) for sale to third parties; and treat the remaining “dry” gas to the specifications appropriate for use as fuel or raw materials by third parties.

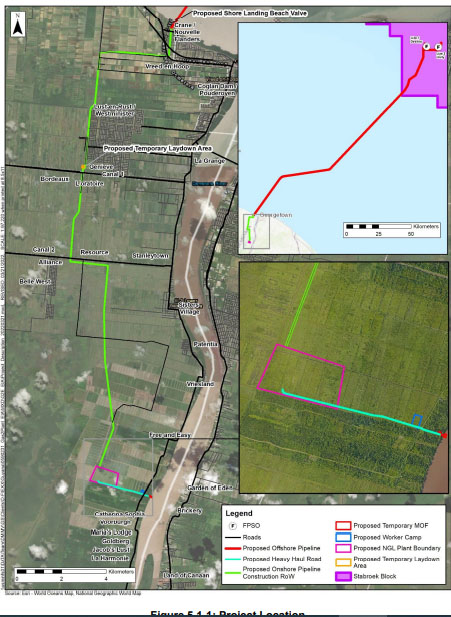

Crane/Nouvelle Flanders

The pipeline is expected to land at Crane/Nouvelle Flanders, West Coast Demerara and make its way to Wales on the West Bank of the Demerara.

The government’s power plant is expected to utilize the “dry gas” for electricity generation. The impacts of that power plant were not addressed in the EIA for the pipeline since it will not be constructed by EEPGL.

EEPGL estimates the current project cost at approximately US$1.3 billion (GY$260 billion) and adds that a “higher certainty cost estimate” will be developed following the negotiation of all major contracts. The company states that if all approvals are granted in a timely manner then it is aiming for an early start on construction.

“…a target date of August 2022 for start of NGL Plant site preparation and will take approximately 3 years. The combined offshore and onshore pipeline system is targeted to be ready to deliver rich gas by end of 2024, and the NGL Plant is targeted to be operational by mid-2025. The Project has a planned life cycle of at least 25 years,” the EIA document states.

It added that the project aims to employ approximately 800 workers during the peak construction stage, 40 full-time workers during the operation phase and about 50 persons during the decommissioning stage. Furthermore, ERM said that the EPA has already issued a no-objection letter authorizing “selected early works activities” that will support the main construction. The early works entail upgrading, rehabilitating and repairing approximately 6 bridges and 11 kilometres of road along the West Bank Demerara Public Road from Patentia towards the NGL plant site.

“The early works activities will also include the establishment of an approximately 5-hectare laydown area to stockpile aggregate, which is needed for the early works road improvements. All road and bridge improvements are expected to generally remain within the existing road RoW (right of way),” the document states.

The project will be executed in three phases – construction, operation and decommissioning. It entails three aspects as well – an offshore pipeline which is approximately 220 kilometres of a subsea pipeline extending from new subsea tie-ins at the Destiny and Unity FPSOs in the Stabroek Block to the proposed shore landing, located approximately 3.5 kilometres west of the mouth of the Demerara River; onshore pipeline that is a continuation of the offshore line and extends about 25 kilometres from the landing site to the NGL plant; and the NGL plant and associated infrastructure that will be located about 23 kilometres upstream from the mouth of the Demerara River on the west bank.

The document states that both the Destiny and Unity FPSOs have pre-installed facilities to allow for the export of the associated gas with crude production.

“Each FPSO will have the capability of exporting the full 50 MMscfd (1.4 MMsm3/d) design gas flow for the Project and will be able to control export rates to as low as 10 MMscfd (0.28 MMsm3/d). The current plan is for the Destiny FPSO to typically provide approximately 30 MMscfd (0.85 MMsm3/d) and the Unity FPSO to typically provide approximately 20 MMscfd (0.57 MMsm3/d) of natural gas,” it informed.

Pipelines

The onshore pipeline will require an approximately 23-meter-wide temporary construction RoW, which will be expanded in certain designated areas—primarily to accommodate the additional area needed for horizontal directional drilling (HDD) of the onshore pipeline beneath some features such as roads and canals. Typically, HDD entry and exit locations each require an area of 50 meters by 100 meters. The onshore pipeline permanent operational RoW will be approximately 12 meters wide.

There is no designated RoW for the offshore pipeline. The area of disturbance for the offshore pipeline installation will be a function of the equipment selected to install the offshore pipeline in the portions of the offshore pipeline where the pipeline will be buried.

According to the EIA document, the offshore component of the pipeline will have an 18 kilometres length which will be used to transport the associated gas. It noted that in water depths greater than 600 meters, the offshore pipeline will be laid directly on the seabed while it would be laid on the bottom or buried in depths between 20 and 600 meters. For water depths less than 20 meters up to the approximately 1.6-meter depth, the pipeline will be laid in a trench for protection purposes at a depth sufficient to achieve a minimum cover of 1.2 meters.

Meanwhile, for the nearshore segment, the offshore pipeline will be installed by pulling in on the seabed or through a drilled bore. For the shore crossing segment, the pipeline may be installed using either HDD or open-cut trenching techniques.

For the onshore segment, with a design capacity of 120 MMscfd (3.4 MMsm3/d), the pipeline is expected to transport natural gas from the shore landing to the NGL plant. EEPGL will construct an aboveground shore landing beach valve which will demarcate the boundary between offshore and onshore. The valve will be used to control the flow of gas within the pipeline and can be used to shut down the line for maintenance and inspection.

According to the document, the aboveground valve compound will be equipped with anti-cut/anti-climb perimeter fencing around the valve, with fibre optic intrusion detection, 24-hour-per-day closed-circuit television monitoring of the compound, and security lighting.

The pipeline will be installed below ground with a minimum cover depth of 1.22 meters along with a fibre optic cable system in the same trench for communication and to detect leaks/third party intrusion. The only aboveground facilities associated with the onshore pipeline other than the valve will include a cathodic protection system to help prevent corrosion of the underground pipeline facilities.

“Another short segment of piping will extend from the NGL Plant to the planned third-party Power Plant site, to deliver dry gas to the Power Plant. Since the location of the Power Plant has not been finalized, the route for and length of this length of piping is not yet known; however, it is assumed for the purpose of this EIA that the Power Plant will be located within less than 1 kilometre of the NGL Plant,” the EIA identified.

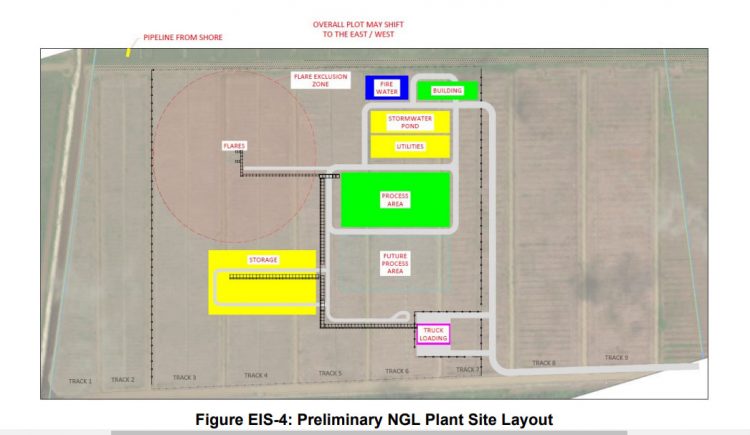

The NGL plant is expected to include a Metering skid, located at an inlet receiving section, to measure the volume of gas delivered to the NGL Plant, a slug catcher / liquid separation, and a heated pressure letdown station to reduce the incoming pressure of the gas to plant operating pressure; mercury and H2S removal facilities; an NGL Recovery Unit to extract NGLs and dehydrate the gas to the specifications required for use as fuel for the Power Plant; various utility systems necessary to support plant operation; a flare system to accommodate safety, operational, and non-routine flaring, as needed; NGL storage and truck loading facilities; and an additional metering skid on the Power Plant delivery pipeline, which will serve as the point of custody for transfer of natural gas to the Power Plant.

Alternatives

EEPGL and the government explored a number of other means of alternative sources of energy but ultimately settled on natural gas since it is a more reliable source as opposed to wind, solar and to some extent hydro. The study also informed that EEPGL commissioned a desktop and field survey looking at the feasibility of 20 potential sites for the pipeline and the NGL plant. However, in the end, the abandoned cane fields with low biodiversity was chosen since it is farther from established neighbourhoods.

The study notes that the selected route minimizes geotechnical and constructability challenges, and does not conflict with existing subsea infrastructure, including cables belonging to Guyana Telephone and Telegraph and fibre optic cables belonging to EEPGL. In addition, the offshore pipeline follows the same general corridor of the EEPGL Fiber Optic Cable for approximately half of the route to minimize the overall footprint and optimize the use of the seafloor.

Additionally, a “no project” alternative was also considered.

Impacts

Overall, ERM and its associates deem the impacts of the project to range from negligible to moderate after they would have assessed a number of factors. The EIA said that while the project, with both onshore and offshore components, will have a range of potential impacts on the physical, biological (marine, freshwater, and terrestrial) and socioeconomic environment, it will also generate benefits for Guyanese through increased employment and increased energy reliability.

The EIA concluded that during both the construction and operation stage there will be sound and vibration impacts and persons will be subjected to higher than normal noise levels. Additionally, the air quality is expected to be impacted due to dust and other emissions from all three phases of the project.

However, ERM said that suite of embedded controls will reduce emissions to air. Additionally, based on the assessment of pre-mitigation significance levels for potential impacts on air quality, a suite of mitigation measures is recommended to address potential Construction stage air quality (dust) emissions.

Air quality dispersion modelling was conducted for the NGL Plant operations and concluded that predicted maximum ground-level concentrations of criteria pollutants will be no more than 5.4 per cent of the associated World Health Organization (WHO) and U.S. Environmental Protection Agency (USEPA) ambient air quality guideline concentrations.

The EIA also informed that approximately 6.62 hectares of benthic habitat will be lost as the offshore pipeline is being laid. However, the impact of this is rated from negligible to moderate. There will also be some terrestrial displacements during the laying of onshore pipeline and construction of ancillary infrastructure, but ERM said that majority of terrestrial wildlife species in the area are common, generalist species with moderate to high tolerance for human disturbance.

ERM says that there could be a potential cost of living increase due to a higher demand for some goods and services, either through direct Project procurement or through Project worker purchases. Furthermore, it is very likely that women will not have equal access to Project employment opportunities with Guyanese businesses unless they are directly targeted for recruitment. However, to offset the gender imbalance, EEPGL will develop contract language for pipeline and NGL Plant contractors encouraging recruitment and training of women for various Project-related construction roles, as well as advertising the types of goods and services they will procure locally.

Additionally, EEPGL will establish new temporary marine safety exclusion zones associated with the major installation vessels during offshore pipeline installation in the Construction stage. It is anticipated that these temporary marine safety exclusion zones, which will move with major installation vessels during the construction stage, may impact commercial vessels that operate in deeper waters and artisanal fisherfolk vessels that operate in shallower waters – in particular in the nearshore offshore pipeline segments and at the shore landing site.

The zones are expected to remain in place during the operation stage which means that fishing activity will be prohibited to prevent damage to the infrastructure. However, the EIA said that the impact is negligible owing to the small number of operators that currently participate in deep-sea fishing.

Based on the EIA, several aspects of relocation would have to occur. It identified one residential property, four dwellings along with agricultural lands. This impact was assessed as moderate since it affects the lives and livelihoods of those that would have to either move or minimize their farming space. It also noted that EEPGL will support the Government of Guyana to develop and implement a Resettlement and Livelihood Restoration Strategy aligned with international standards.

Unplanned events

Though the EIA states that accidents with the pipelines and NGL plant rarely occur, it did address some of the scenarios where this can happen. It noted that there are a number of factors that can lead to leakages in the pipeline and they include corrosion, a buildup of stress in the pipe wall and objects hitting the pipeline.

ERM states that should a subsea pipeline become damaged resulting in the release of natural gas then a gas plume will rise from the seafloor to the surface and can cause fires or explosions when it encounters an ignition source.

The consequences would likely be much less severe offshore than a release from the onshore pipeline because an offshore release would be extremely likely to be free-field, thereby negating the chance of an explosion.

“To reduce the likelihood of a release, the offshore pipeline design and installation will vary depending on the pipeline depth. At a minimum, the pipeline will be laid in a trench, with sections closer to the nearshore area buried, which will reduce the likelihood of an external impact causing a release. The offshore pipeline will be constructed using international good practices, which will reduce the likelihood of stresses building up in the pipeline walls and thereby reduce the likelihood of buckling. A leak would be quickly detected and isolated using emergency shutdown valves, which will limit inventory loss and therefore the duration of any release event,” the EIA states.

ERM says that onshore pipeline integrity failures are rare, especially on such relatively short lengths of pipeline as in the case of the project. If a loss of integrity were to occur, the most likely causes would be a third party striking the line or corrosion of the pipe that ultimately led to a pipe wall failure. Explaining what could happen should an onshore pipeline develop a leak, ERM says that a flammable gas cloud would be formed and this could ignite, causing either a flash fire or explosion. An explosion would only be likely to occur if the gas is released into a congested space.

The project will include a number of embedded controls to reduce the likelihood of a third-party line strike, which includes pipeline markers installed along the onshore pipeline corridor, indicating the location of the buried pipeline and including standard signage to not excavate in the area prior to contacting EEPGL and a fibre optic cable-based system installed along the pipeline at the time the pipeline is buried, to detect leaks and/or third-party intrusion the pipeline, among others.

The EIA said that there will be numerous layers of protection to prevent a release of natural gas from the NGL Plant but noted that the “specifics of these design elements will be developed during the detailed design of the Project. In the unlikely event that multiple layers fail, however, there is the potential that some of the scenarios analyzed have the potential to impact resources outside of the NGL Plant boundary.”

The types of events assessed for those scenarios with the potential to impact resources outside the NGL Plant boundary included a boiling liquid expanding vapour explosion (BLEVE), a flammable gas cloud, and a jet fire.

A BLEVE can be caused when the contents of a pressurized storage tank are heated by an external heat source such as a fire. The contents of the tank can start to boil, thereby increasing the pressure inside the tank until it exceeds the tank’s design pressure, which can ultimately result in a failure of the vessel. At the point of failure, the tank can explode, creating an overpressure and a fireball.

The overpressure from a BLEVE typically results in considerably more damage to the surrounding environment than the thermal radiation from a fireball, so the assessment is focused on BLEVEs. Such events are very rare in natural gas processing facilities, and several protection measures will be put in place to prevent such failures, such as pressure relief valves, firefighting systems, and industry-standard separation distances between storage vessels.

The EPA will now have to assess the EIA and determine whether it addresses the scope of work after as well as factor in objections during the 60-days comment period. During the Yellowtail project review process, a number of consultations were held and it is unclear if the EPA will follow the same process for the gas to energy project.