-opposition has questions

Huge amounts of material have had to be purchased to stabilize the soil at Wales for the over US$1b gas to energy (GtE) project, drawing concerns from the opposition and raising questions as to whether all investors in that area will face similar expenses.

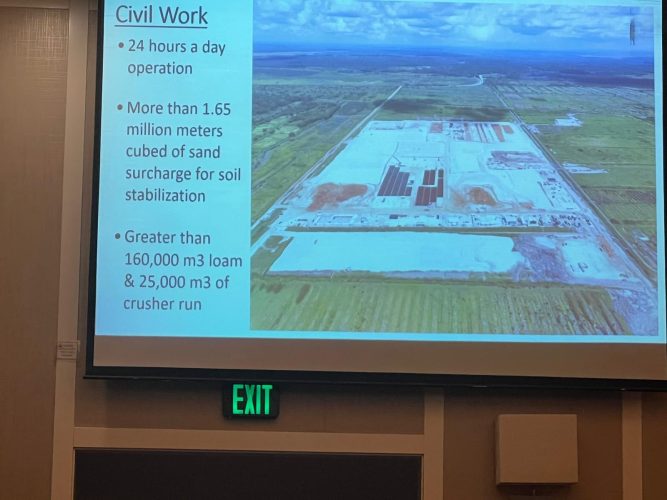

Project lead for the Wales, West Bank Demerara GtE project, Winston Brassington, on Thursday made a presentation to an American Chamber of Commerce event at the Marriott Hotel and disclosed that 1.65 million cubic metres (m3) of sand had to be brought in for soil stabilisation. In addition to the sand, he said that 160,000m3 of loam and 25,000m3 of crusher run had to be used for the stabilisation exercise. This would have been at a significant cost which was not disclosed.

The need for such soil stabilising has raised the question as to whether Wales was the appropriate spot for this project taking soil characteristics and other factors into consideration or it was purely a political decision to rejuvenate the area in the aftermath of the closure of the sugar estate there by the previous government.

And given that government has announced plans for the former Wales Sugar Estate area to be converted into an industrial zone with many factories there, the opposition is questioning whether companies investing in the zone will also have to dole out millions of US dollars to remediate their lands before construction.

“We have been asking and asking what exactly was the issue given that there was disclosure from the company and now [government] that there was soil remediation and stabilisation. What exactly was the problem with the soil? Was the soil type not strong enough for the foundation? Was it pegasse, meaning too loose and had to be stabilised? Is there additional costs for this remediation? It is the public’s money and they should know,” geological engineer and former University of Guyana lecturer, Sherwood Lowe, who is APNU’s lead public relations person told the Sunday Stabroek on Friday.

“Soils can be resolved through engineering solutions and it seems that it has been, given that there is currently pile driving at the site. However, we are all in the dark on what really happened,” he added.

PNCR economic advisor and party treasurer, Elson Low, added that party representatives had earlier this month revisited the site and observed pile-driving activity, unlike the soil stability processes it had seen the month before. Low noted that it was concerning to the party that for nearly a year, soil remediation was conducted at the site without government stating whether there were any additional costs or the exact reason for the works.

“What we have observed is that they finally began pile driving; but in the earlier months of this year, we visited the site and they were working on remediating the soil. And then they had said they were working on remediating. That meant that up to a week ago they were still doing that and it was concerning to us that they were spending almost a year remediating the soil,” he told this newspaper.

Low said that it is concerning to APNU because given that government has said that Wales will be an industrial area and that they are hoping that many factories will be set up there, the party wants to know if the amount of monies spent on soil remediation for the GtE project will also be needed to be spent by other companies that want to build there.

“If there are heavy industries there, does that mean that every large factory has to remediate their lands for nearly a year before they can build? This is the same government that said Clonbrook was rejected because of it being swampy lands. Now if this is good soil and companies have to spend one year remediating before building, it is implied that building [costs] for this industrial park is going to be very substantial,” Low contended.

“The expenses for soil remediation can be very substantial [given] the sand and earth they had to dump there. A heavy industry being developed there will be very costly it seems,” he added.

He said that while a gas-to-energy project is needed for this country, the one being built at Wales is not the best option and the opposition will hold to that position.

Among the reasons given for their stance, the APNU+AFC economic advisor explained that they were told by ExxonMobil that the pipeline now costs some US$120 million more than if the project had been based in Berbice.

“Based on the initial study, this project has cost the Guyanese people… we are seeing them paying now US$120 million [more] for the pipeline because it is much longer, to reach to Wales and which is something we confirmed with Exxon,” he said.

“It is alarming the amount of money involved and given feasibility studies were done and then still having this…,” he added.

The opposition had earlier this month, criticised the government’s management of the Wales GtE Project, highlighting ongoing issues with soil remediation at the site.

Low had pointed out that despite previous assurances, the foundation for the plant was yet to be laid due to unresolved soil deficiencies. The opposition party had then also expressed concerns about the suitability of the Wales site for industrial development, questioning whether it was a viable location given the extensive soil remediation required.

They also challenged the government to release any existing soil assessments for public scrutiny and provide a realistic timeline for the project’s completion.

Lowe also pointed out that studies done had ranked Wales the lowest in site prospects and this is why questions about soil structure are still relevant.

Withstand

A source close to the process explained to the Sunday Stabroek that the soil at the project site had the capacity to withstand weight of only one tonne per meter square but ExxonMobil’s requirements was that it be 20 tonnes per meter square.

“The load that is going to be imposed is 20 times what the soil could take. Therefore, we had to get tech fabric and the sand and a crusher run aggregate and all of that to upgrade it to meet the demand for the project need or its bearing pressure,” the source explained .

Asked if the same weight bearing pressure would be needed for other infrastructural projects in the planned industrial zone, the source said that it would depend on what was being built but as it is all projects “would require some amount of investment in soil remediation “.

“The ground as is at Wales can only take one tonne per square meter right now. This is because there [Wales] has, like the rest of the coastal plain, very soft coastal clay. That is why we don’t have large structures on the coast. So there aren’t any industrial facilities that can be built there as is. So it depends on what is being built but they all have to (do remediation), if they want a proper facility,” the source added.

Meanwhile, Brassington said that expectations are for the commercial startup of the power plant using lean gas from the power plant in the second half of 2025. In addition it is expected that the combined cycle would be completed by the end of next year.

The project lead also announced that government has added another phase to the project, given that it has realised that the 300 megawatts (MW) of power would not be enough.

“You will see in the papers tomorrow, an advertisement for phase two of the gas to energy project. Already at 300MW, we are projecting that we are going max that out by 2027. We will need more power. The pipeline that is being built has the capacity to handle up 125cf of gas. Our commitment from Exxon is 50cf. The government hopes to secure additional gas to build a second phase power plant,” he said.

He pointed to lands set aside for “future developments” and “downstream activities. “Being a fertilizer plant or whatever. We will need to build additional storage for the liquids.” He noted that the project delays are due mainly to soil stabilisation works which took longer than anticipated. “The soil stabilization has taken a lot longer. It has been a very technical process. So the civil schedule is what is driving, a very critical part, the other items are a little behind but not as much as the civil schedule,” Brassington said.

“But all of this being said, the parties have agreed that sometime in the second half of next year, I don’t want to be precise right now because there are a number of moving parts, but we believe that this will be achieved,” he added.

He said that ExxonMobil’s task of bringing the pipeline to shore is on schedule for the end of this year and they will fill it with nitrogen and await the completion of the plant.

Using slides in his presentation, Brassington said that the US$760 million project was more than just a power plant, as he pointed to the components that will make up the facility.

‘A lot of people may simply think we are building a power plant; we are building an LNG (Liquefied Natural Gas) facility,” he said.